Products

styrene monomer for EPS production

styrene monomer for EPS production,

Expandable polystyrene raw material, Styrene monomer used in Expandable polystyrene, styrene used for EPS,

Synthetic styrene is an important raw material for industry because it is the chemical ‘building block’ for creating a multitude of versatile plastics and synthetic rubbers with beneficial properties including strength, durability, comfort, light weight, safety and energy efficiency. The key styrene derivatives include:

Styrene monomer is typically converted or ‘polymerised’ into pellets which can be heated, fused and moulded into plastic components.

polystyrene (PS)

expandable polystyrene (EPS)

acrylonitrile butadiene styrene (ABS)

styrene butadiene rubber (SBR)

unsaturated polyester resins

styrene butadiene latices

As a result, nearly everyone encounters styrene-based products in some form every day. Materials made with styrene can be found in many familiar items including food and drink containers, packaging, rubber tyres, building insulation, carpet backing, computers and reinforced fiberglass composites such as boat hulls, surfboards and kitchen countertops.

The majority of styrene is used in the production of polystyrene for items such as medical devices, household appliances, drinks cups, food containers and refrigerator door liners.

Expandable polystyrene

Expandable polystyrene (EPS) is a derivative used to create a lightweight but rigid foam used in home insulation, as a protective packaging material, as padding inside bicycle and motorcycle helmets and car interiors, in road and bridge construction, and to build film-set scenery. Composite EPS products may also be used in bath and shower enclosures, automotive body panels, boats and wind turbines.

Styrene enables manufacturers to enhance components in a way that helps to: make cars and trains lighter and more fuel-efficient; reduce dependence on costly natural resources such as tropical hardwoods, marble, granite and natural rubber; and improve the energy efficiency of homes through more effective insulation.

Product Features

| CAS Number | 100-42-5 |

| EINECS No. | 202-851-5 |

| H.S. Code | 2902.50 |

| Chemical formula | H2C=C6H5CH |

| Chemical Properties | |

| Melting point | -30-31 C |

| Boling point | 145-146 C |

| Specific gravity | 0.91 |

| Solubility in water | < 1% |

| Vapour density | 3.60 |

Synonyms

Cinnamene; Cinnamenol; Diarex HF 77; Ethenylbenzene; NCI-C02200;Phenethylene; Phenylethene; Phenylethylene; Phenylethylene, inhibited; Stirolo(Italian); Styreen (Dutch); Styrene (CZECH); Styrene Monomer (ACGIH); StyreneMonomer, Stabilized (DOT); Styrol (German); Styrole; Styrolene; Styron; Styropor; Vinylbenzen (CZECH); Vinylbenzene; Vinylbenzol.

Certificate of Analysis

| Property | Data | Unit |

| Bases | A level≥99.5%;B level≥99.0%. | - |

| Appearance | colorless transparent oily liquid | - |

| Melting point | -30.6 | ℃ |

| Boiling point | 146 | ℃ |

| Relative density | 0.91 | Water=1 |

| Relative vapor density | 3.6 | Air=1 |

| Saturated vapor pressure | 1.33(30.8℃) | kPa |

| Heat of combustion | 4376.9 | kJ/mol |

| Critical temperature | 369 | ℃ |

| Critical pressure | 3.81 | MPa |

| Octanol/water partition coefficients | 3.2 | - |

| Flash point | 34.4 | ℃ |

| Ignition temperature | 490 | ℃ |

| Upper explosive limit | 6.1 | %(V/V) |

| Lower explosive limit | 1.1 | %(V/V) |

| Solubleness | Insoluble in water, soluble in alcoho and most organic solvents. | |

| Main application | Used for manufacturing polystyrene, synthetic rubber, ion-exchange resin ,etc. | |

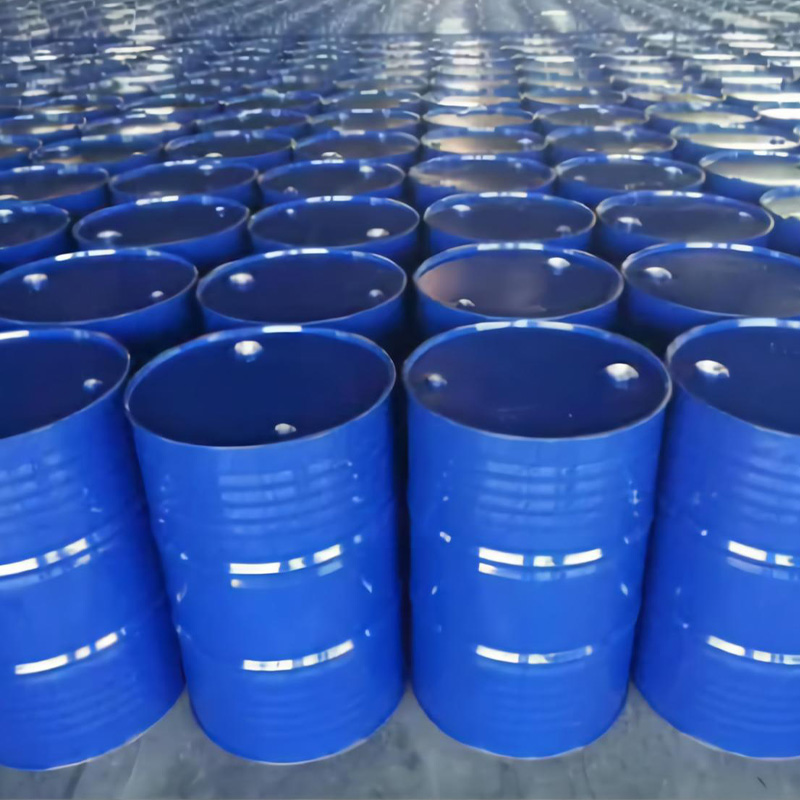

Package and Delivery

Packaging Detai: Packed in 220kg/drum,17 600kgs/20’GP

ISO TANK 21.5MT

1000kg/drum, Flexibag, ISO tanks or according to customer`s request.